- Home >

- What we do >

- Fabrication

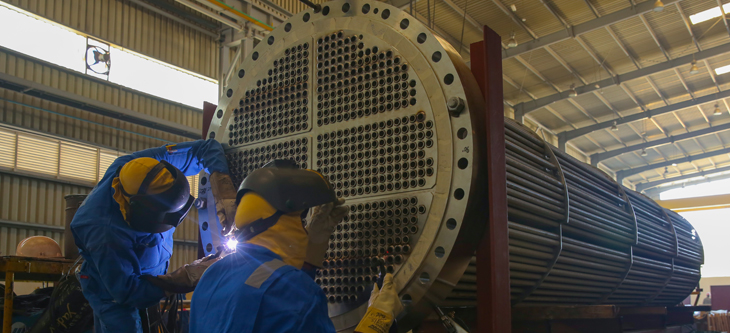

Fabrication

STS operates two specialized fabrication workshops in Oman, located at Nizwa and Sohar industrial zones covering a total area of 125,700 sqm.

We have covered fabrication areas in excess of 24,500 sqm. with effective fabrication height of 10.5 m under hook and single lift capacity of 800MT within the facility. Both the shops are equipped with modern facilities. Our Nizwa facility has inhouse cold rolling capacity upto 239 mm.

Our facilities are well equipped with state-of-the-art fabrication & welding machinery such as CNC cutting, metal forming, welding, heat treatment, machining and material handling equipment. Facilities also include dedicated bays for heavy fabrication, vessel fabrication shops, dish forming area, machine shops and seperate areas for fabrication of exotic materials welding.

The Facility also includes a 3,000 sqm. of covered maintenance shop to cater to pump maintenance, machining, valve repair, testing, refurbishment and calibration.

This site is best viewed in IE 9, Chrome, Firefox and Safari